PRODUCT

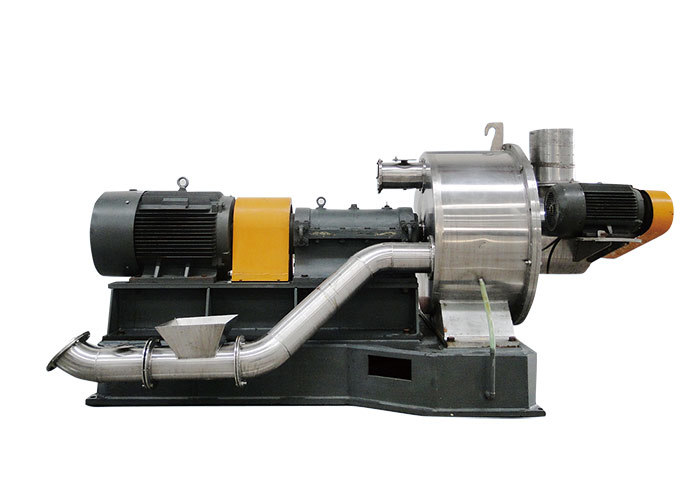

Baking soda pulverizer

碳酸氢钠(小苏打, NaHCO3)可以用作烟气脱硫的吸附剂。它通过化学吸附去除烟气中的酸性污染物,同时,它还可通过物理吸附去除一些无机和有机微量物质。此工艺将碳酸氢钠细粉(d90:20um)直接喷入140-250℃高温烟气。在高温下碳酸氢钠分解生成碳酸钠Na2CO3、H2O和CO2。

Category:

Keyword:

Description

Baking soda pulverizer

1.Basic principle of sodium bicarbonate for flue gas desulfurization

Sodium bicarbonate (baking soda, NaHCO3) can be used as an adsorbent for flue gas desulfurization. It removes acidic pollutants from flue gas through chemical adsorption, and at the same time, it can remove some inorganic and organic trace substances through physical adsorption. This process sprays sodium bicarbonate fine powder (d90: 20um) directly into high-temperature flue gas at 140-250 ° C. Decomposition of sodium bicarbonate at high temperature produces sodium carbonate Na2CO3, H2O and CO2.

pic

The newly generated sodium carbonate Na2CO3 has a high degree of reactivity at the moment of generation, and can spontaneously react with acidic pollutants in the flue gas as follows:

2NaHCO3 → Na2CO3 + H2O + CO2 ↑

Na2CO3 + 2SO2 + H2O → CO2 ↑ + 2NaHSO3

Na2CO3 + SO2 + H2O → H2O + CO2 ↑ + Na2SO3

2. Combination of grinding system:

① On-site direct injection negative pressure process form

pic

In this process, sodium bicarbonate enters the crushing and classifying machine ③ from the raw material warehouse ① through a controllable feeder ② (spiral or star valve). The amount of feed can be arbitrarily adjusted according to the concentration of pollutants before and after desulfurization and the desulfurization effect. After the sodium bicarbonate is ground by the grinder, qualified fine powder is sprayed by a conveyor fan to the desulfurization terminal (furnace or flue gas pipe) ⑤.

The process is suitable for the pulverizer installed in the desulfurization site at a short distance. It can be ground and sprayed at the same time. Sodium bicarbonate is not compacted, and it is efficient and stable. The crushing zone is in a negative pressure running state, the dust does not overflow, and the production environment is excellent. The fan is running with material, and a fast cleaning port needs to be designed to periodically clean the bonded material of the impeller to ensure the stable operation of the system.

② On-site direct injection positive pressure process form

pic

In this process, the conveying fan ④ is installed in front of the crusher, and the raw material bin ① is controlled by a controllable feeder ② The measured raw materials are blown into the crushing and classifying machine ③ in a positive pressure form. The powder is directly sprayed to the desulfurization terminal (furnace or flue gas pipe) ⑤.

This process is also suitable for the pulverizer installed in the desulfurization site at a short distance. The material does not pass through the conveying fan, there is no sticking phenomenon, and the fan does not need to be cleaned. However, the crusher is in a positive pressure running state. In order to ensure that the dust does not overflow, there is a high requirement for the sealability of the crusher, and a wind lock feeder ⑥ must be installed between the crusher and the feeder ⑥ or directly through the inverter Control the wind lock feeder.

③Proximity feeding form of independent crushing unit

pic

In this process, the crusher is designed as an independent system. Qualified materials are first collected by a collector and then delivered to the material terminal by a fan on a quantitative basis. The process will install a crushing device within a radius of 500 meters from the material terminal. Each system is self-contained. Integrated, independent work does not interfere with each other, both economical and convenient on-site direct injection and mobile flexibility of remote feeding.

④ Transfer form at remote grinding station

pic

For desulfurization sites that are not suitable for establishing application conditions under online crushing and desulfurization conditions, this process can be used to crush sodium bicarbonate to the target particle size (d90: 20um), transported by tanker to the powder silo on site, and sprayed by the powder spray system To the desulfurization terminal. This process can be used with large-scale crushing units to provide centralized grinding and multi-point feeding, and has the advantages of flexible maneuverability, wide radiation surface, and strong operability.

Products

Welcome your message consultation